DESIGNING IS OUR GAME

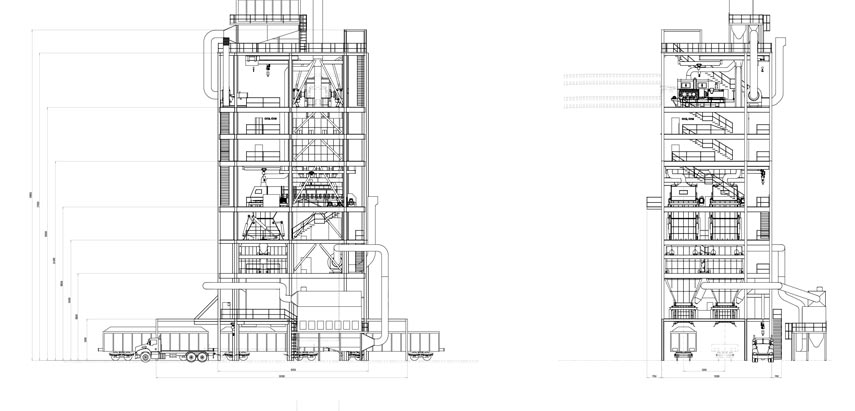

NV5500N – BOGATYR TRAIN LOADER - NOEN, a.s.

General description

The automated loader for continuous loading of material (primarily coal) into a passing train.

The loader is capable of automatically filling the passing train while making full use of each wagon. Filling takes place with a maximum deviation of ±0.5 % from ideal wagon topping-up. This applies despite the fact that no connected information exists about a train (e.g. order and capacity of wagons). This is detected by scanning the train at a sufficient distance from the loading tower. An optimum coal dose is then prepared (weighed out) for each wagon and subsequently discharged to it uniformly.

Coal is supplied to the loading tower from an external stockyard by means of a belt conveyor.

Under certain conditions, the tower is even capable of filling two trains at a time.

The tower concept is designed so that the entire plant can be extended to the double capacity, when another almost identical tower is used. Both buildings can then be interconnected from the construction point of view, and rail gauge of all the tracks can be the same.

All the plant is designed with respect to environmental protection. The loader building is clad and sealed, the transfer points are to the maximum extent also sealed and in addition exhausted – all that to reduce dustiness in the surroundings of the train loader.

Main parts of plant:

– Driving station of charging conveyor

– Main storage tank serving as buffer stock

– Discharging belt conveyor

– Two-way lead-in with unique system of flaps

– Set of weighing storage tanks

– Set of telescopic filling spouts

– Exhausting and filtering systems for elimination of dustiness of transfer points

Main parameters of harbour terminal machines and equipment

| Total weight of installed equipment | 1,600 | t |

| Conveying capacity of equipment – theoretical | 5,500 | t/h |

| Bulk density of material to be loaded | 1.15 | t/m3 |

| Ground-plan dimensions of equipment: | 14 x 18 | m x m |

| Height of equipment | 40 | m |

| Capacity of main storage tank | 350 | m3 |

| Max. speed of train during filling | 0.4 | km/h |

| Maximum size of wagon | 80 | m3 |